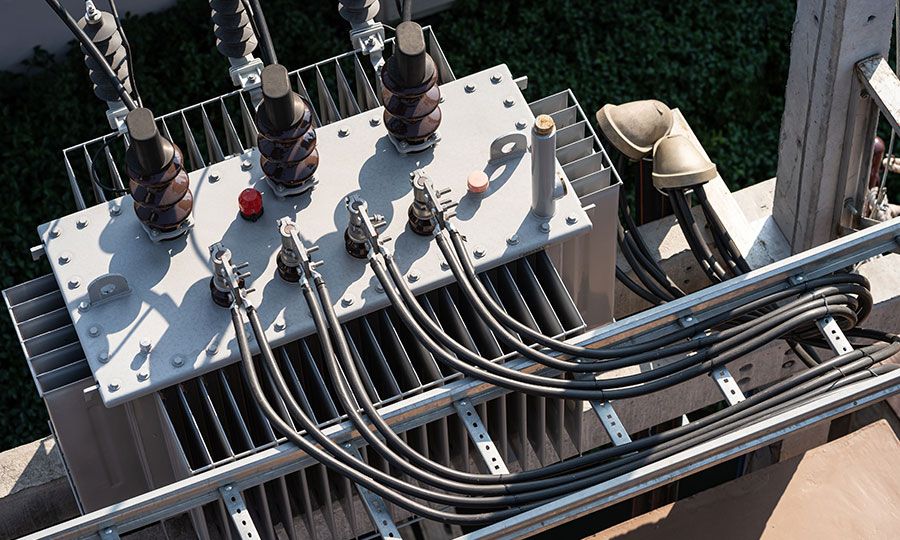

Better Products to Control Transformer Oil Leaks and Drips

Transformer oil leaks and drips are a concern for utility companies, and they have been for decades. Today, as we focus more on reducing our effect on the environment, it’s even more critical for the industry to ensure compliance while staying within a budget.

Environmental Coordinators with electric utility companies spend countless hours on the road traveling to substation sites to ensure leaks and drips aren’t causing ecological damage. And a big part of that mission is to make sure any transformer oil leaks and drips are cleaned and contained within the substation.

Traditionally, for these types of clean-ups, the industry has relied on white spill sheets and socks that haven’t been improved in over 40 years. Unfortunately, these materials make that mission difficult, messy, and time-consuming. And they don’t work well outdoors, which can lead to environmental pollution.

The problem with outdated spill control products.

There are two major problems with these outdated spill materials that render them relatively ineffective outdoors.

- No rain water can be absorbed by these products

- They begin to break down quickly in the sun

-

PROBLEM #1: No Rain Water Absorbed

Traditional spill control products cannot absorb water, and when it rains, the rainwater pools on top. Since transformer oils are lighter than rainwater, any oil falling onto a wet white sheet becomes runoff. As a result, the oil leak gets carried away to pollute our soil, rivers, and lakes.

According to the National Academies of Sciences, Engineering, and Medicine, over 20 million gallons of runoff oils enter the ocean from North American each year. And one gallon of that oil has the potential to pollute a million gallons of groundwater. That’s a lot of polluted water!

-

Problem #2: Outdated White Sheets Break Down in the Sun

The second fatal flaw is that old-fashioned spill control materials begin to break down almost immediately in UV sunlight. As they are exposed to the sun, the spill pads and socks disintegrate. The spill sheet fiber loses as much as 70% of its strength in only one week and will soon crumble into a fuzzy powder.

Unfortunately, the leaky oil doesn’t just stay in one spot. Rainwater lifts the oil from stone and concrete and carries it away. I’ll bet you’ve noticed the “stain” of where the rain pushes the oil.

Rooftop UV Degradation Test

Click here to see the results of our year-long Rooftop UV Degradation Test.

The challenge. Managing transformer oil leaks in the field.

One substation engineering analyst explained that he had become a slave to the old white spill sheets. He needed to make weekly trips to check the spill sheets and socks. He wanted to be sure the spill sheets weren’t falling apart and causing ground contamination. However, due to the number of sites he monitored, he couldn’t get to every location each week.

In cases where he may not return as quickly, he had to remove and replace partially-used sheets because they would not last until his next visit. So he was throwing away money to save time. But he had no choice due to the instability and unreliability of his resources.

Dark stains show where these outdated white spill products failed.

The surrounding gravel then gets contaminated and needs to be replaced.

After 29-years in the industry, he knew the importance of containing oil leaks and drips. And he knew that if he left a spill pad in place too long, one of two things would happen:

-

Sun damage would cause the pad to break down and blow away.

Sun damage would cause the pad to break down and blow away. -

Raindrops would coat the surface of the white sheets. And, when oil dripped onto the slick surface, the oil would get washed into the surrounding gravel.

Raindrops would coat the surface of the white sheets. And, when oil dripped onto the slick surface, the oil would get washed into the surrounding gravel.

Either way, he wasted time raking up white sheet remnants, shoveling oily stone, and placing them into a drum for disposal. Then he would have to replace the gravel and the barely-effective sheets and start all over again. He was dismayed to learn that three drips per minute produced a gallon of spilled oil in only 17 days. And he was shocked to know that that same gallon of oil could contaminate up to a million gallons of groundwater. The weight of his responsibility sat heavily on his shoulders.

The old pads would disintegrate in the sunlight after a while,” the analyst said. “And, because we’d use them over rocks or soil, we’d have to rake and remove the contamination by hand. Then, the soil and rocks would have to be placed in drums for proper disposal. Plus, we worried about run-off.

It was not uncommon for him to find that the rain had carried the transformer oil leaks to the far reaches of the substation gravel. Every year, all the oily gravel would need to be removed and replaced in as many as ten substations. At the cost of up to $7,000 per substation, you’re talking serious money.

The solution. Better products to control transformer oil leaks and drips.

Instinctively, he knew there had to be a way to reduce the amount of time and money he spent chasing leaking oil at the substations. Fortunately, a colleague introduced him to Spilltration® Husky PolyBack products by HalenHardy. An in-person demonstration by the Spilltration team showed him how the Husky products work differently.

Spilltration® Husky products are engineered to work differently:

-

First, the novel Husky materials lasted up to two years in the outdoors. On the other hand, the old white sheets only lasted a week or two.

-

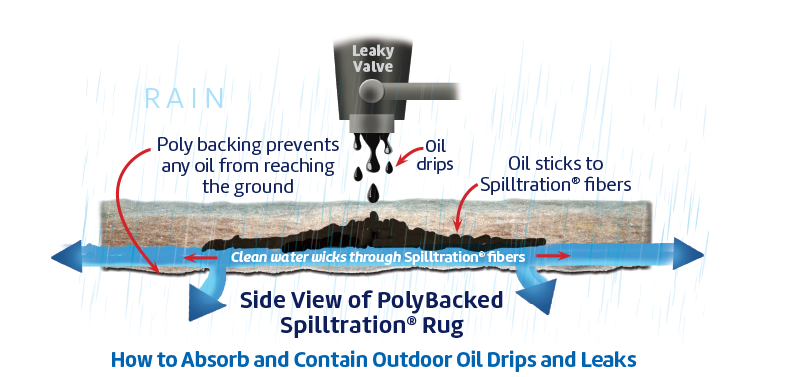

Second, Husky pads don’t repel water. Instead, they act as a filter. Rainwater flows through the pads and is cleanly wicked away. The water doesn’t pool on the top, creating a water slide that carries the leaking oil into the ground. The oil flows into the pad fibers and sticks there.

-

Third, the polyethylene backing (PolyBack) prevents the trapped oil from reaching the ground through the bottom of the pad. This means that once an area on the pad reaches its saturation point, the oil is pushed to other parts of the pad, rather than pooling on the top or draining out the bottom. Husky pads will naturally hold up to 10x more leaking oil as a result.

The demo convinced the analyst that Husky products would not only save time and money. In addition, he could virtually eliminate his cleanup time of crumbled white sheets and oil-polluted gravel.

The results. HalenHardy products worked better.

At first, he was skeptical and continued checking on the substations at the same weekly pace. But over the next few months, his faith in the Spilltration® Husky PolyBack pads increased. The time between his visits grew longer, and he noticed that he had more time to focus on other responsibilities. The Husky pads saved him numerous trips to substations, and they provided him with peace of mind when he considered the reduced risk of damaging the environment.

We went through rolls and rolls of old white sheets servicing a 1,000-square-mile plus territory,” he noted. “When I consider labor, travel, materials and disposal, Spilltration products help us reduce our overall oil leak and spill control costs by 50% to 70%. Our colleagues at several sister utilities report similar results.

His upper management also saw the value in his discovery, which increased his value to his employer. Husky products created a triple win out of a no-win situation. Spilltration® products worked longer and more effectively to contain oil leaks safely from the utility transformers. Plus, switching to Husky PolyBack enabled him to reinvest the time he had previously spent traveling into other projects, making him more effective at his job.

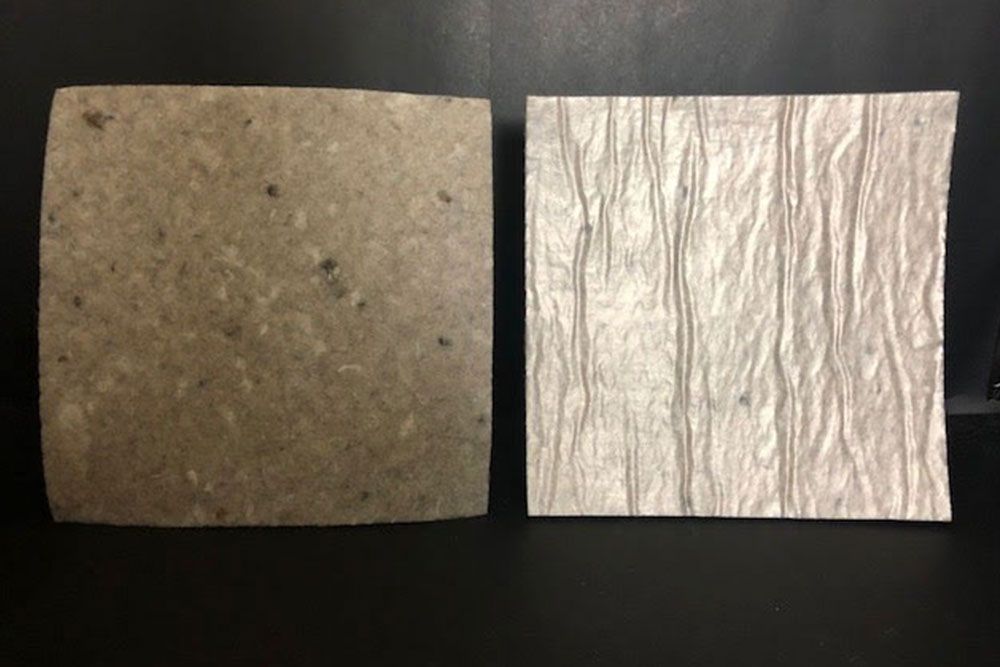

Husky PolyBack products have two sides… a thick, absorbent Spilltration top side (left) And a leak-proof polymer backing to prevent oil leaks from reaching the ground (right).

Three years later, Spilltration® Husky PolyBack products take a licking and keep on wicking.

Three years after that first Spilltration Husky demonstration, his road trips to transformer sites occur monthly – not weekly. Yet, the Husky products continue to perform at a high level and help him defeat his most formidable outdoor foes- the sun and rain. Plus, he adopted a much more environmentally-friendly process.

Spilltration Husky PolyBack rugs hold onto leaky transformer oil while allowing clean rainwater to filter through. Notice the surrounding gravel remains clean and oil free. This saves the utility 50% to 70% over old fashioned white spill sheets.

And a sustainability bonus! Spilltration® Husky fibers are made from post-consumer waste.

Husky products’ unique design absorbs and traps the oil while allowing clean water to filter through into the ground. And, because the Spilltration fibers are made from post-consumer waste, they help support your company’s sustainability initiatives.

Partner with HalenHardy Team

We’re dedicated to finding solutions to your problems and providing ongoing training and support.

HalenHardy also compliments their products with a very helpful train-the-trainer system. They help new clients receive thorough, consistent education from the experienced HalenHardy team. Most importantly, the analyst said he found HalenHardy to be a partner he could brainstorm with when new, unexpected challenges arose. An electric utility Environmental Coordinator client noted:

We barely have time to cover our daily duties as it is. So, when new problems arise, we have to lean on our best suppliers to help us solve them.

The HalenHardy team listens to us and has always found solutions to meet our needs. They’re constantly trying to meet the utility industry’s needs and come up with innovative ideas to help protect the environment. When we encounter a situation, they develop with a plan and continually have new and unique solutions. We bounce a problem off of them and they definitely help us develop a solution that will work. That’s priceless in my book.

Get to know Spilltration® Husky Polyback Products

Need some help choosing the right spill control products?

Contact us if you have any questions or need help finding the right spill control products. Our Customer Success Team is available by chat or by phone at 814-822-2004.