-

CASE STUDY: Substation Oil Leaks, Environmental Manager, Major Electric Utility

Electric Utility saves time and money with Spilltration® Products

One of an East Coast Utility’s ongoing corporate environmental goals for each of their companies is “Zero Preventable Reportable Spills.” Not surprising for a corporation that has well-established Environmental Management Systems and has maintained their ISO 14001 certification since 2008.

Identifying and managing environmental risks at each site plays a major role in these efforts. An almost constant risk – and headache – for Mark Stasuk, an environmental manager for 30+ sites, was capturing persistent oil leaks from substation transformers so that they wouldn’t be discharged every time there was a rain event. Although persistent leaks aren’t usually thought of as a “spill,” when even one drop of dielectric fluid hits navigable waters, it becomes a reportable.

The Problem with Drip Buckets and Pans

Through the years, different solutions had been implemented and failed. Metal drip pans didn’t hold up to the coastal weather. Plastic drip pans and buckets filled with rainwater, and since dielectric fluid is lighter than water, the oil was the first thing to overflow when the pans reached capacity, not the water.

After a rainstorm, Oil Drip Pans and Buckets fill up with water and overflow.

The Problem with White Spill Pads

White spill pads were a better option because at least they didn’t overflow. But, cleaning up the mess made by the white pads made his crew’s cleanup jobs harder, not easier. “For years, we have been discouraged by the ineffectiveness of white spill pads and socks. They degrade to flakes in the sunlight, blow all around the site and allow oil to wash out in rainy weather,” Stasik explained.

Sometimes, the white pads would degrade in as little as two weeks. In addition to collecting all of the flakes that blew across the sites, crews would then have to shovel out the oil-stained gravel and replace it with fresh gravel before placing fresh absorbent pads under each leak. Month after month.

Even when the white sheets didn’t degrade, they still weren’t foolproof. Each time it rained, the pads became coated with rainwater. Then, when oil dripped onto the water-coated pad, it would simply roll off; staining the shale around the pads and creeping across the concrete toward drains and vegetated areas.

The situation was far from ideal, but for decades, white spill pads were about the only option; other than emptying drip pans after each storm event or creating underground vaults to capture and separate oil from stormwater.

Rain carries the dripping oil away from the old white spill sheets.

In sunlight, white sheets turn to dust in just a few weeks.

The Solution: Control Substation Oil Leaks with Spilltration® Husky Pans

So, when Stasuk saw HalenHardy’s Spilltration® Husky Pans, he was skeptical but decided to give them a try: because they couldn’t be much worse. Not only did the pans hold up to the weather, but they also minimized the time his crews spent maintaining each substation.

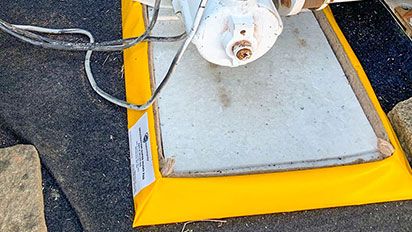

After sweeping and vacuuming up the degraded white spill pad flakes and shoveling out the oil-soaked gravel, Stasuk’s crews replaced the gravel and positioned a Husky Pan under each persistent leak. The pans were weighted down in the corners to prevent them from moving.

The Husky Pans stayed exactly where they were placed and captured the oily leaks while filtering out clean rainwater and snowmelt. Microfilter weep holes around the base of each pan allow the clean water to flow out of the pan so there is never an overflow.

Because the absorbent Husky Fibers capture oil as well as fine sheens, the gravel and concrete around the Pan don’t become stained: so there’s no more shoveling and replacing gravel or buying expensive bioremediation products to clean up the oil stains. As the Husky Pads in the Pan become saturated, they can be replaced in less than 10 seconds.

“Spilltration® Husky products don’t degrade in sunlight and last for months and months. So we’re saving time and money. Plus, we are using a product made with recycled materials,” Stasuk said. This helps him meet sustainability goals, minimize cleanup time and better protect the environment.

Shop Husky Pan Products

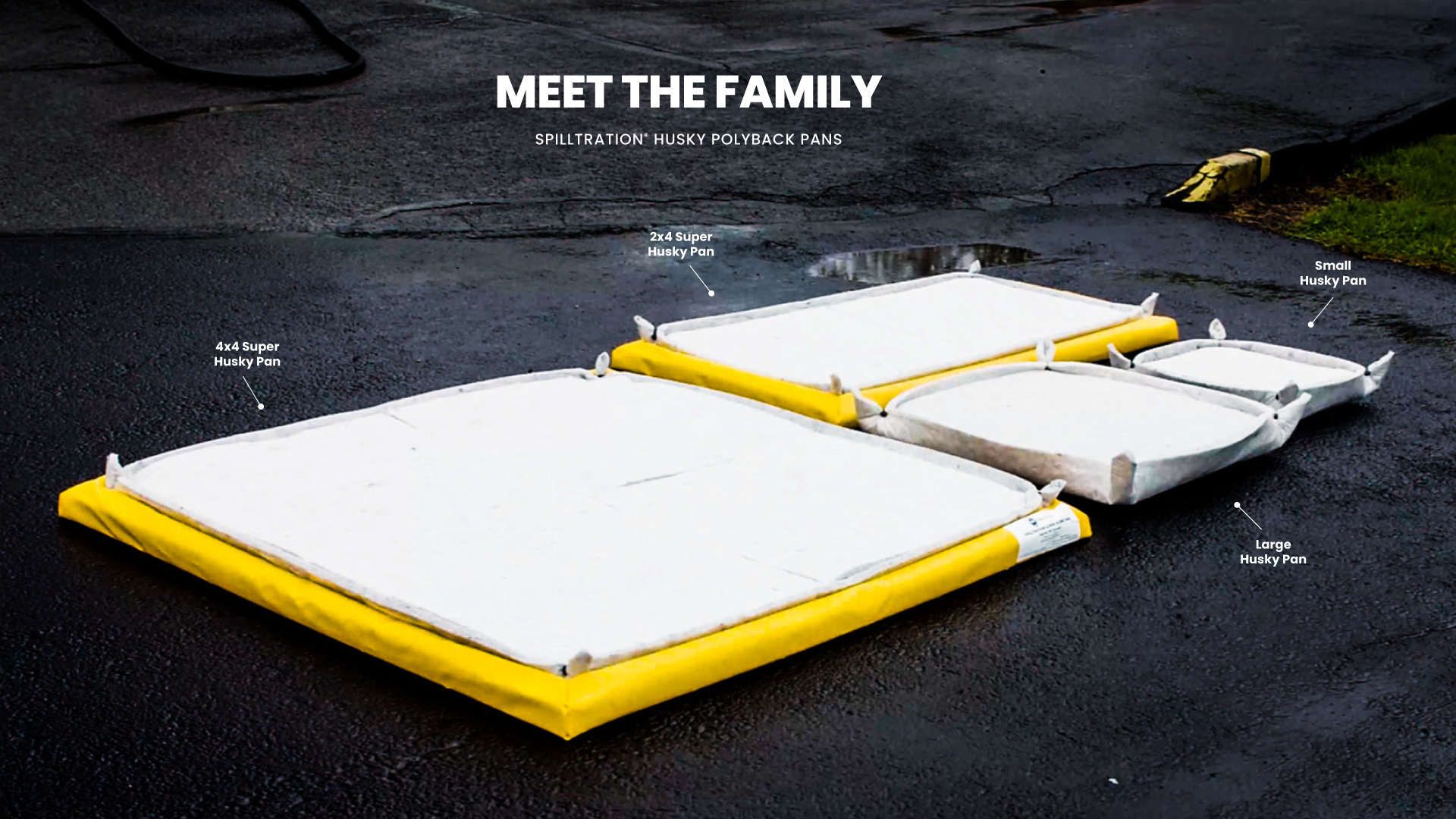

Husky Pans are available in a variety of sizes, so you can find the perfect one for your needs. Use our Dripulator Guide to calculate how often you need to change out your Husky Pan to ensure optimal performance.

Related Articles

-

In the Lab: UV Degradation Test

-

Product Comparison Videos: White Spill Sheet vs Husky Pan, Rival Drip Pan vs Husky Pan

-

Download: Husky Pan Dripulator Guide

Need some help choosing the right spill control products?

Contact us if you have any questions or need help finding the right spill control products. Our Customer Success Team is available by chat or by phone at 814-822-2004.