Prevent Silt and Oil Sheens from Being Discharged into the Harbor with HuskyGuard® Storm Drain Filters

With gantry cranes in near-constant motion and cargo being staged in the yard for the next leg of its journey, marine terminals are busy places. It takes highly skilled operators working with great precision to load the lines of trucks and railcars that arrive and depart each day.

Keeping everything running smoothly is a practiced art that requires equipment to be rugged and reliable. But between trucks that drag dirt into the facility, unpaved areas that get muddy when it rains, fuel leaks, and hydraulics that sometimes fail, it can be nearly impossible to keep silt and oil sheens in check.

Daily Best Practices to Prevent Water Pollution

Preventing water pollution means implementing good housekeeping practices throughout the terminal that help to minimize the potential for spills and other forms of pollution. From routine sweeping to minimize the amount of dirt tracked to and from an area to catch trays that capture leaks and drips when fluids are transferred; the small efforts that are made daily add up.

Being prepared for larger spills is also essential. Stocking spill kits in areas where fluids are transferred helps trained employees to contain and control spills quickly, reducing the risk of discharges.

Managing Stormwater Runoff with In-drain Solutions

Spills typically don’t happen every day. They’re also not the most common reason for Stormwater Permit violations. More often, it’s oil sheens and Total Suspended Solids (TSS) that cause a bulk of non-compliance issues.

Being located near waterways means that marine terminals often need to deal with stormwater runoff from adjacent roads and properties as well as the rain that falls onto the property. That makes storm drains essential in most terminals to help prevent flooding. But these drains usually lead straight to the harbor – which means that if there isn’t a plan in place to capture oil sheens, dirt and debris before it reaches the storm drain, rain will lift it and drag it straight into the harbor.

It’s not always practical or possible to capture oil sheens and dirt before they reach storm drains. It’s also not practical to permanently close or cover the drains. In-drain solutions help marine terminals to solve common non-compliance problems and simplify maintenance.

In an ideal world, engines wouldn’t leak oil, hydraulic lines wouldn’t burst and dirt wouldn’t get tracked all over the place. Until those ideals can be realized, implementing best practices fills the gap to help prevent water pollution.

Simplify Stormwater Compliance

Best management practices (BMPs) are most likely to be followed when they are simple, realistic and easy to implement and maintain. Installing in-drain stormwater filters is a proven BMP that provides a last line of defense for capturing dirt and oil sheens before stormwater is discharged.

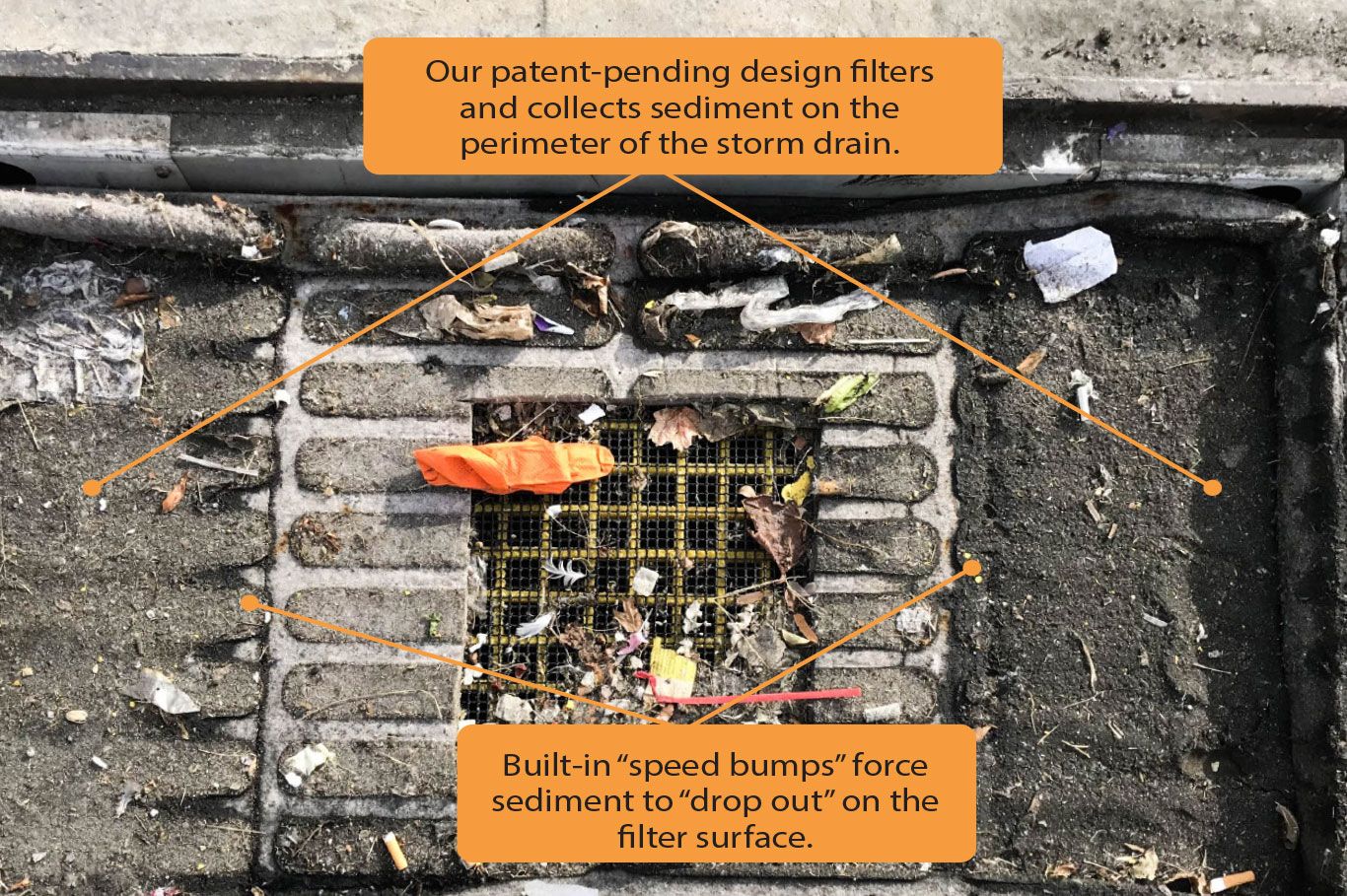

In-drain stormwater filter inserts have been around for about two decades without much innovation or improvement – until recently. HuskyGuard® Oil and Sediment Drain Filters capture oil sheens and sediment while overcoming common storm drain insert issues such as:

- Torn bags that render the insert useless

- Bags collapsing under the weight of collected sediment

- Storm drain backups due to bags falling into drains and blocking outlets

- Lengthy maintenance due to bags falling to the bottom of storm drain catch basins

- Ineffective oil absorbing media that allows oil sheens to be discharged

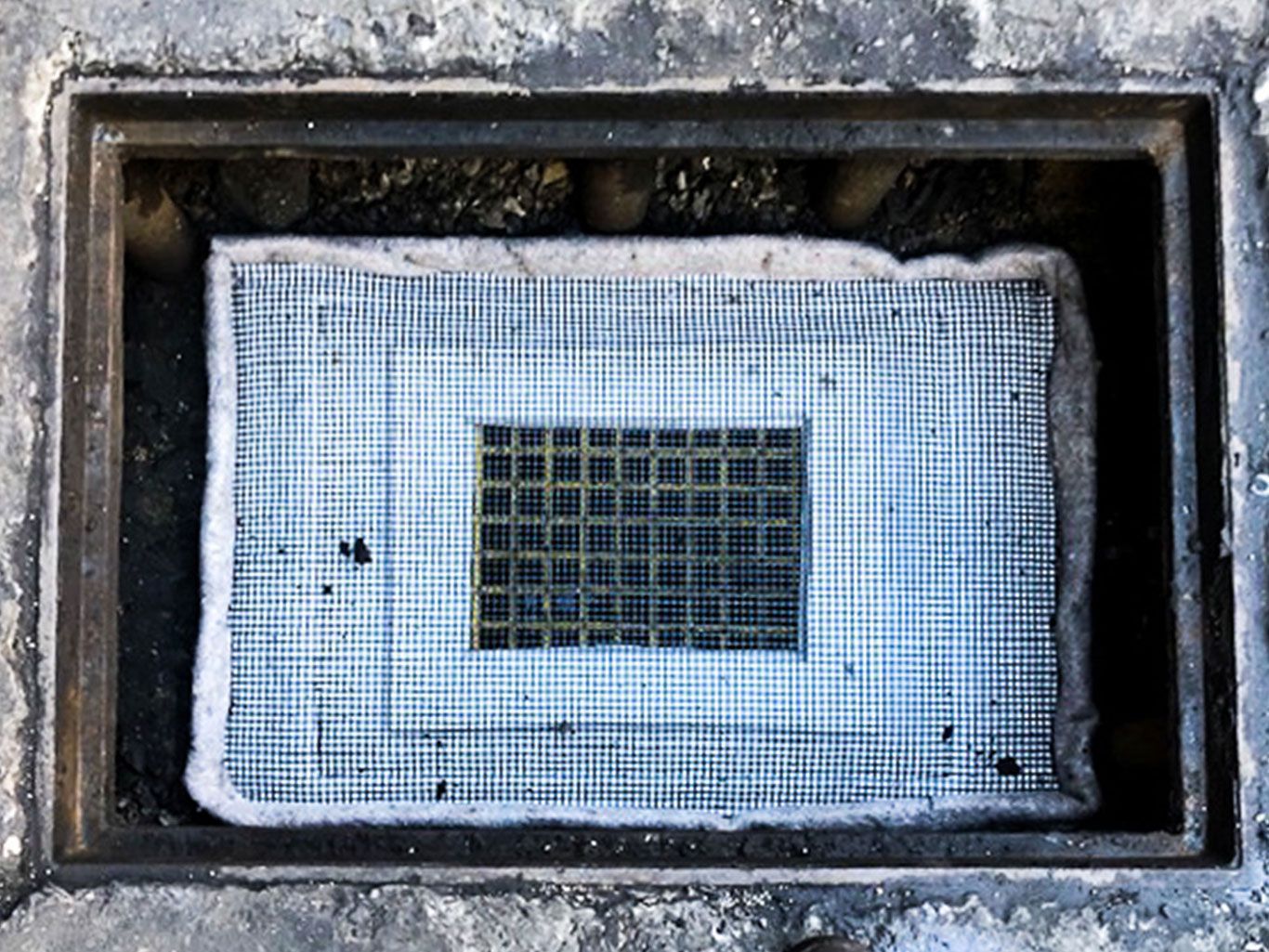

Maintaining storm drains and preventing sediment and oil sheen from being discharged is simplified with HuskyGuard® Drain Filters. Instead of relying on the weight of the storm grate to hold the filtering media in place, the HuskyGuard® filtering media is placed on a frame that is set just below the storm grate. Initial installation takes less than 30 minutes and facilitates fast, easy inspections, maintenance and filter replacement.

With HuskyGuard® Oil and Sediment Drain Filters:

-

Dirt, sediment and debris can be easily swept up after rain events

- Routine maintenance takes less than 2 minutes with no need to lift the drain grate

- Replacing the oil filtration media takes less than 5 minutes, and is only necessary when the media has become fully saturated

- The system is less likely to capture biologicals that lead to malodor complaints

- Below-grade outflows remain clear, preventing backups and flooding

- Oil filtration media is effective in capturing oil sheen, preventing discharges

- No bags that fall into the drain or get torn due to sharp debris

Tight schedules and high traffic can make routine storm drain maintenance difficult and even unsafe. Installing HuskyGuard® Oil and Sediment Drain Filters in storm drains cuts maintenance time and costs while preventing drain backups and pollutant discharges.

Related Articles

Shop HuskyGuard®

ORDER TODAY

Call our team directly at 814-822-2004 or email sales@halenhardy.com.