Space Saving Sorbent Solutions

Who’s ever heard of a SmooshKit®? SmooshKits are one of the most practical and effective sorbent solutions available in the spill response industry today. If you work around heavy machinery, transformers, or in any mobile outdoor environment, you already know about leaky machinery and equipment. You’re probably also familiar with the messy tasks of hydrocarbon containment and cleanup.

When we think of oil spills, we tend to think of those huge tankers or pipeline spills that we see on the news. Did you know that those account for only 8% of the millions of gallons of oil that enter our waterways every year? You don’t hear much about the leaks and spills due to equipment failure or operator error. A whopping 80% of all hydrocarbon spills occur on land and find their way into waterways!

Would it shock you to know that the major sources of oil leaks on land are due to automobiles and heavy equipment? Even equipment in perfect running order tends to leak oil. And these releases of oil are the ones we often overlook.

- Auto part recyclers

- Biodiesel processing

- Commercial filling stations

- Crude oil production

- Electrical substations

- Fleet vehicles

- Heavy construction equipment

- Maintenance facilities

- Mobile mechanics

- Mining

- Oil and gas exploration

- Power plants

- Railyards

- Transformer yards

- Transportation

- Utilities transmission and distribution

Spill Response Challenges

Most of the time, your work is performed in remote locations. If a leak or a spill happens, there may be a significant wait time until emergency responders arrive on the scene, leaving you to contain the mess until help arrives. And, since the Oil Pollution Act of 1990 holds the facility owner or operator legally and financially responsible for the release of oil, you’re left in a challenging position.

There is never enough storage space for sorbent materials. Even if you work on-site, you have limited space to store adequate amounts of spill control products. Lack of storage is a considerable problem if a spill happens because you’re usually left without sufficient materials to contain the spill.

You don’t have room in your work truck or fleet vehicle for bulky spill kits. If you’re on the road, you know you’re only working with a few cubic feet of room at best. Once you fill that space with people, tools, and equipment, you don’t have much room for 5-gallon bucket spill kits (that are mainly air).

Introducing the Space Saving SmooshKit®

You’re probably familiar with traditional white sorbent booms and pads that take up too much space and are ineffective at best. At HalenHardy, we know that space is a precious commodity, so we developed a solution to one of the biggest challenges in mobile industries- storage space. We created our patented Smooshable™ vacuum compression technology that squeezes our Spilltration material into compact packages that can fit virtually everywhere. Say hello to SmooshKit.

Spilltration + SmooshKit Technology

Have you ever heard of our Spilltration® line of products? They’re our line of sorbents for spills that work in wet conditions. Yep, you heard that correctly. Spilltration products absorb hydrocarbons and filter clean, clear water through. Oil sticks. Water wicks.

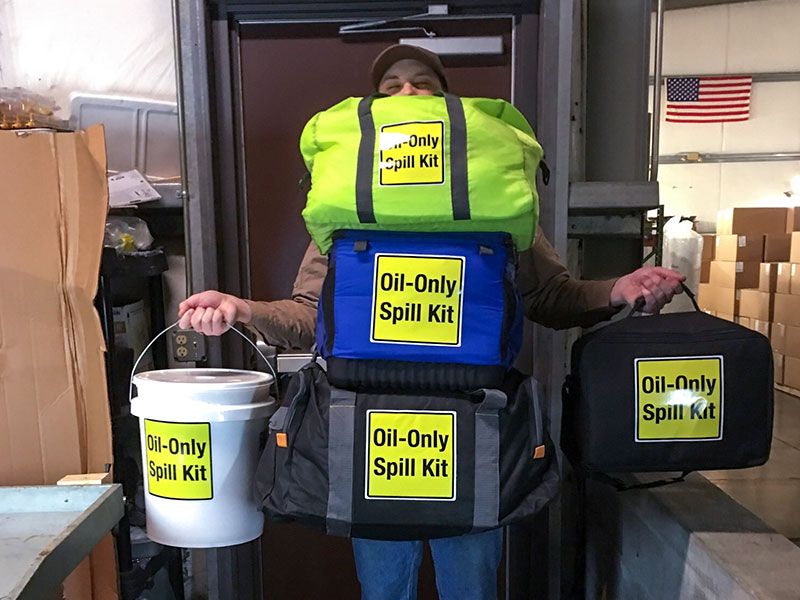

We took our Spilltration line and upped the ante. You can now maximize what you can pack into your emergency response vehicles, service trucks, fleet vehicles, heavy equipment, and even your pickup truck—practical, effective solutions when and where you need them. Just take a look at all the places you can stuff, stack, cram, or wedge SmooshKits.

-

Under your seats

-

Behind your seats

-

Between your seats

-

Inside seat pockets

-

In your toolbox

-

In utility boxes

-

In the trunk of your car

-

In all your nooks and crannies

“Over the past year, I have deployed Spilltration SmooshKits in countless incidents. With the limited space I have on our trucks and trailers, Smooshkits fit in the tightest spots. This allows us to carry plenty of supplies to clean up oil and fuel spills everywhere we respond. Saves time. Saves money.”

Oil Spill Solutions for Mobile Applications

When it comes to oil spill cleanup in mobile applications, you need solutions that work. Outdated spill control products are ineffective on today’s job sites. They’re bulky, heavy, hard-to-use, and don’t work well in wet conditions. It kind of makes you wonder why it’s taken this long to find a better way. Well, it’s taken time to find the perfect balance between size and absorbency.

We know the most important aspects of oil spill response are containment, control, and stabilization. Just as crucial is how long it takes to control the situation. Time is critical. You don’t have time to waste lugging around heavy materials that are difficult to deploy.

Why are SmooshKits Better?

1. Space

Spilltration® SmooshKits® are 500% smaller than standard spill kits! You can stack them and pack them wherever your heart desires. This means that no matter how small your storage space is, you will always have enough spill containment solutions on hand.

And here’s a little secret, most of the competitor’s 5 gallons kits only contain about 3.5 gallons of absorbent materials. The rest is just a bucket. So, it’s bigger and bulkier with less absorbent power! Who wants to pay for a bucket?

2. Efficiency

What makes the SmooshKit® so efficient? For starters, it’s so lightweight that you no longer have to break your back lugging spill control from your storage location to the spill site. You can even store it under the seat of your truck or between your seats! Within seconds, you can put your spill control plan in action.

3. Speed

Since it’s lighter and less bulky, it’s a breeze to deploy. It deploys up to 4x faster than traditional sorbents. When it comes to spill control, speed is everything. Plus, your workers don’t need extensive training to know how to use it! The process is less complicated than other types of oil spill control products, so you can get to the job of containing the spill faster.

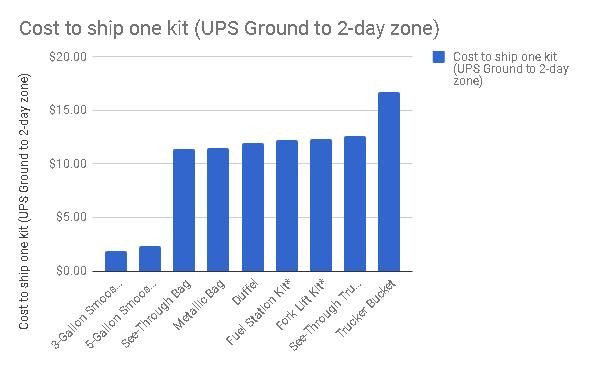

4. Save on Shipping

It’s compact and lightweight, saving you in shipping costs. On average, you’ll spend 86% less on shipping costs. 86% less—that’s huge! Take a look for yourself:

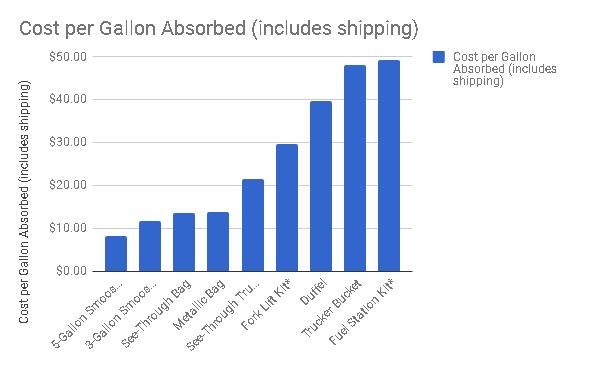

5. Cost Savings and Sustainability

Not only do you save money in shipping costs, but you save money on the cost per gallon of oil or fuel absorbed. And they’re reusable. Simply wring it out and use it again and again! Better for your wallet and our environment.

- Decreased storage costs

- Decreased transportation costs

- Decreased disposal costs

- Decreased material costs

- Decreased cleanup costs

- Decreased labor costs

Are you ready to cut your costs and try something new?

If you struggle with a lack of storage space in your mobile applications or remote locations, SmooshKits are the perfect solution for you. Toss a few in the cab of your truck or under the seat, and you have spill control you can count on. Anytime. Anywhere. And just like our entire Spilltration line, they’re reusable (up to 10x), and they don’t give up in the rain. What’s more, they’re made from materials that were headed to a landfill.

Minimize waste and reduce your carbon footprint with environmentally responsible spill control. Now, you can feel good about your sorbent selection. And guess what? They’re proudly made right here in the USA!

You don’t need to feel stuck with ineffective and bulky sorbents that fail to deliver. If you aren’t satisfied with your current spill control program, it’s time for an upgrade!

Spilltration® Original Oil Spill SmooshKit®

Spilltration® Mechanics’ Oil Spill SmooshKit®

Spilltration® Basic Oil Spill SmooshKit®

When you need it done right. On time. On budget.

Give us a call at 814-822-2004.