Prevent Secondary Containment System Overflows and Oil Discharges with Drainiac® Oil Water Separators

With unprecedented storms and flooding happening in some regions and extended droughts happening in other areas, correctly sizing outdoor secondary containment systems to adequately allow for run-on can be a challenge. The traditional 25-year, 24-hour storm and 110% estimates may no longer provide enough protection.

Employee retirements and labor shortages add to the challenge because field service technicians have more on their plates than ever. The ideal theory of being able to drain every secondary containment system immediately after each rain event may not be possible. That makes all of the undrained systems more susceptible to overflows if there is another storm event before they can be drained.

As an environmental engineer, your clients look to you to help review and update their environmental plans with the innovative technologies and solutions that will help them stay in compliance and minimize the risk of violations. They probably don’t want to re-build their secondary containment systems to allow extra capacity for run-on. They’re also likely to prefer solutions that don’t require time-consuming or expensive maintenance.

Time, Labor and Cost Intensive

- Leave valves open after systems have been drained

- Drain systems with oily sheens

- Allow sediment to be discharged with collected stormwater

- Abandon draining the system because of frozen water

One alternative to manually draining secondary containment sumps is to contract a vacuum truck to remove accumulated water. But, waiting for the truck to arrive can be just as time consuming as manually draining each system. It’s also a more expensive alternative.

Engineering Controls Minimize Maintenance Times

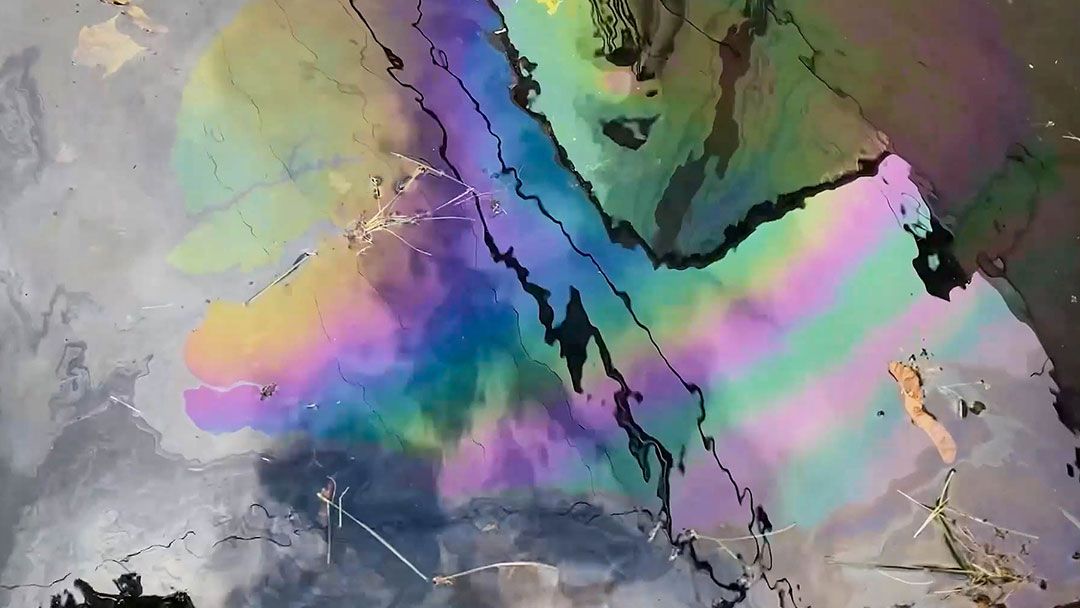

Automating the draining of secondary containment sumps saves time and money – and it can be accomplished without extensive and costly retrofitting. The EPA recognizes oil-water separators as a stormwater management technology. The Drainiac® Petroleum Filter Valve is an oil-water separator that can be incorporated as an engineering control to capture oil sheens and allow collected rainwater to drain from secondary containment systems.

Because the Drainiac® is a passive filtering device, it doesn’t rely on a person being present to manually drain a secondary containment system. This helps prevent overflows – especially in remote areas that may not be accessible after storms, or those that take a considerable amount of time to reach after a storm.

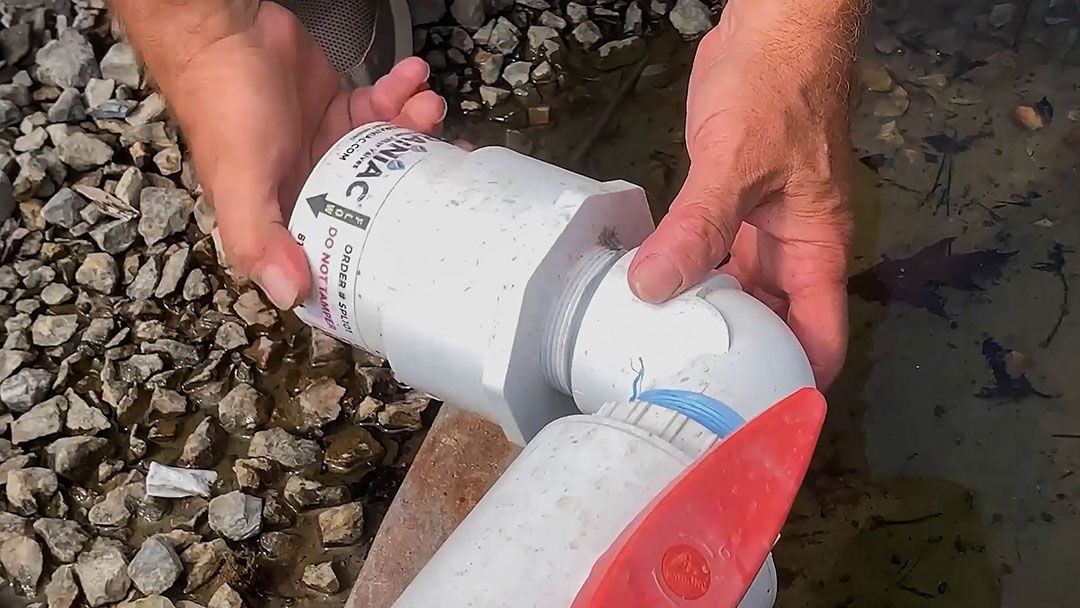

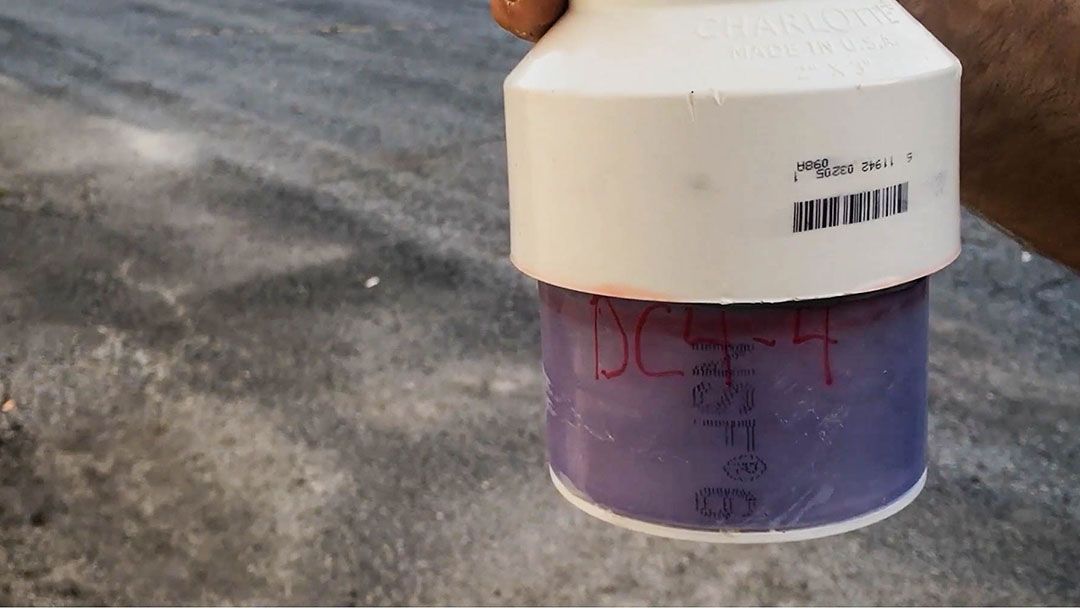

The Drainiac® Filter Valve threads into the outflow port of both fixed or portable secondary containment devices. It contains an oil-selective polymer that allows water to flow through, but swells in the presence of oil. In the event of an oil or fuel spill, the polymer swells to close off the Filter Valve and prevent oil or fuel discharges.

Filters petroleum sheens from secondary containment

stormwater. Produces clean discharge.

Threads into the outflow port of both fixed or portable secondary containment devices.

Filter media automatically swells up and shuts off in case of an accidental spill.

Eliminates manual opening and closing of valves.

Inspection and Maintenance After Storm Events

Because the Drainiac® Filter Valve allows secondary containment systems to self-drain, inspecting and maintaining them after storm events is simpler and faster. Instead of manually opening a valve, waiting for all of the water to drain, then manually closing the valve; the technician simply needs to look for one of the following three conditions:

1) If there is no water in the unit, the water has all drained from the system.

2) If water is still draining through the Drainiac®, it is functioning properly and will continue to drain the remaining water (unless an oil or fuel spill occurs).

3) If there is water, fuel or oil in the secondary containment system and nothing is draining through the Drainiac®, it has reached its oil-absorbing capacity and needs to be replaced.

The self-draining feature also helps to prevent ice build-up in secondary containment systems during freeze/thaw cycles. This helps to increase worker safety when items within the system need to be accessed. It also helps to prevent cracking and aging in concrete, asphalt, plastic, and flexible containment systems.

Five-year SPCC plan reviews and annual SWPPP reviews are excellent opportunities to implement new best practices that will help clients simplify routine maintenance tasks and reduce environmental risk. Drainiac® Petroleum Filter Valves are field-proven to reduce time spent draining systems and decrease the likelihood of secondary containment system failures.

Freezing weather brings on a whole new set of problems with our secondary containment. We have to keep a much closer eye on manually draining our stormwater (from cold rain or melting snow). Otherwise, the containment turns into an ice-skating rink. Last winter, we tested our first Drainiac® filter valve. It worked like it was supposed to. Our containment water was safely filtered all winter, and the sheen was captured inside the Drainiac®. The containment floor remained practically ice-free. Amazing.

Shop Drainiac® Products

Related Articles

NEED SOME HELP?

Call our team directly at 814-822-2004 or email sales@halenhardy.com.