Critical Choice: Oil Spill Containment vs. Cleanup

What would you rather do? Chase down and clean up an oil spill or sheen that’s spread over miles of a stream or contain it before it spreads? The choice is yours.

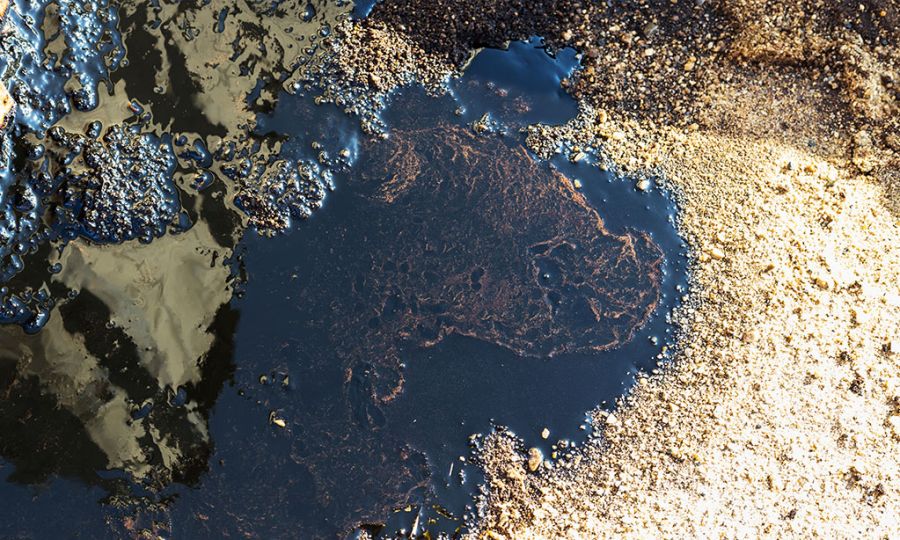

When you think of oil spills, you’re probably thinking of tanker disasters or pipeline spills. Even though those spills can be catastrophic, they’re not that common. Surprisingly, they’re only responsible for 8% of the oil that enters our oceans every year. How much oil is encroaching on our waterways? Tens of millions of gallons. 92% of oil contamination in the environment is often persistent oil leaks and spills from industrial and commercial facilities.

This “invisible oil pollution” tends to go a bit more unnoticed than the big spills we see on the 5 o’clock news.

The Biggest Oil Pollution Culprits

Cars, trucks, fleet vehicles, and heavy equipment are some of the biggest culprits. They’re the primary source of oil that finds its way into soil and nearby waterways. Non-point-sources like roads, parking lots, storm drains, wastewater treatment plants, and sewage systems are also easy access points for oil to pollute the environment.

Oil from leaky automobiles and faulty equipment often drip onto the pavement. In dry conditions, that oil may sit upon the surface for days or weeks. That is… until it rains. Then, the water sweeps large amounts of oil into storm drains and waterways. And, we all know how fun that is to clean up.

Do you want to spend hundreds, thousands, maybe even millions of dollars in oil spill cleanup? Or, would you rather stop oil leaks at the source and contain them for a fraction of the cost?

Every day on your job sites, there is the potential for an oily mess to appear. Even equipment in perfect working order can leak oil. If you work in an outdoor or mobile industry, you see minimal oil leaks and drips all the time. Those pesky little leaks add up to be a big, big problem. The EPA even refers to small oil spill problems as a “death by a thousand cuts.” Your budget doesn’t need to die a slow and agonizing death; there’s a better way.

How prepared is your team to respond to spills quickly and effectively?

Steps You Can Take to Mitigate Environmental Damage

Environmental damages include long-term effects on the ecosystem, harm to marine life and vegetation, and toxic pollution in our drinking water. And that’s not all. Environmental harm, fines, legal fees, remediation costs, and bad publicity are just a few ways oil spills can impact your company. How much would you like to avoid $10,000, $15,000, or $20,000 in fines?

There are steps you can take to mitigate environmental damage. After all, it’s the company’s responsibility to keep oil leaks, drips, and spills under control. And, if you fail to do so, expect to suffer the consequences.

1. Better Containment = Better Results.

HalenHardy® has 35 years of experience in the environmental field. We know the challenges that the industrial workforce faces. Oil leaks and spills are an all-too-frequent occurrence, but here’s the good news. There really is an easy fix.

Most people that work in industrial situations aren’t spill response professionals. Their many talents don’t usually include spill remediation. And, they are typically under-trained and ill-equipped to deal with a spill. To make matters worse, spills never happen at a good time. Think about it. How often have some of your biggest oil messes occurred when you were ready for it? Most of the time, you find yourself facing an oil spill situation when you’re short-handed on staff, low on sorbent materials, or it’s raining outside.

And, here’s the kicker: most traditional spill response products don’t work in the rain. But, thanks to innovation and technology, better options finally exist. Confidently contain spills with solutions specifically designed to work in any weather conditions. Leave the heavy spill cleanup and spill remediation to spill control professionals.

What spill containment options best meet your needs?

Husky Oil Filter Rug

Extra-large for quick and efficient cleanup of diesel, kerosene, hydraulic fluid, motor oil, and other hydrocarbons.

Husky Oil Filter Strips

Use to quickly contain a spill or surround and protect crucial areas.

Husky Oil Filter Pan

Great for placing directly under drips and leaks. Spilltration Husky materials allow rain water to pass through, and absorb oils and fuels.

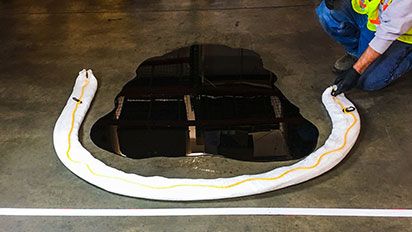

SpillBoa Booms

Rapidly deploying sorbent barriers that can be wrapped around a spill source or around a storm drain to reduce spreading.

2. Better Training

Train workers on the critical steps needed to safely and quickly contain the mess before it becomes an even bigger problem. Don’t forget to educate workers on assessing a spill, how to plug leak sources, how to use spill products, and when to evacuate the area.

If you can’t contain the spill at the source, always protect nearby areas like storm drains, soil, and waterways.

This helps to minimize the reach of oil and its harmful effect on the environment.

3. Be Proactive

Actions you can (and should) take proactively.

- Train workers on proper spill prevention practices when working with oil sources.

- Provide appropriate personal protective equipment (PPE) to ensure safe handling of materials.

- Have a visible worksite map of oil and fuel sources for easy identification.

- Educate workers to know which spill situations they can safely contain and which spills are unsafe.

- Confirm workers are able to quickly locate the spill control products that they need.

-

Oil spills spread 100 times faster in wet weather. So, use specialty spill control materials that can work in wet conditions.

Remember: Time is money. Save both by using effective products that can be quickly deployed.

4. Take Action

Actions for on site.

-

Don’t panic. Rely on thorough training to stay calm and move efficiently.

-

Assess site risks and hazards before jumping into action.

- Safety first. If the situation is unsafe, evacuate.

- Equip workers with necessary PPE.

- Follow your company’s written spill control procedures to notify relevant parties (internal environmental coordinators, spill contractors, emergency responders, EPA, state and local environmental authorities).

- Use containment methods to keep spill from spreading once help is on the way.

- If possible, plug the source of the leak.

- If plugging a leak is not an option or is unsafe, then surround or contain the spill directly at the source.

- If containment isn’t an option, it’s time for damage control. Identify and protect high risk areas like storm drains, waterways and soil.

Spills Happen

Spills happen. Doesn’t it make sense to contain those irritating spills before they become monumental mishaps? Ensure your team is prepared and equipped with the tools and knowledge needed to handle a spill. Their quick thinking can prevent the excessive spreading of oil and environmental damage until spill cleanup professionals arrive on the scene.

-

Take our free “Controlling Oil Spills on Land” Training Course

-

View our top rated products for containing and cleaning up oil spills and leaks.

Want to Learn More?

If you have any questions on finding the right spill control products to meet your needs, our Customer Success Team is available by chat or by phone at 814-822-2004.

For more oil spill containment training, be sure to check out our new “In the Trenches” Video Training Series. Our first course, Controlling Oil Spills on Land, is now available. Signup today – it’s free to enroll.

"In the Trenches" Training

Introducing a mobile-based training series designed to guide your team in fast, effective ways to control and clean up oil spills, sheens, and sediment in stormwater. Developed with and for you by the HalenHardy team.