Secret #7: White Oil Spill Sheets Technology is Outdated

Industry experts estimate that more than 168 million pounds of virgin white oil spill materials are manufactured every year in the USA. After use, the virgin white products tossed into the garbage.

White spill sheets were first developed in the early 1970s, and they haven’t upgraded much in 50 years. In fact, there have only been a handful of upgrades in the white spill sheet product category:

-

In the mid-1980s, ultrasonic bonding helped hold the fibers together better. This technology allowed the industry to make different thicknesses.

-

In the late 1980s, scrim coverings made the outer surface more durable.

-

In the early 1990s, they came up with an anti-static version for work around solvents. And a “fine fiber” edition…whatever that means.

Since then, the manufacturers have focused on cosmetics and packaging. Bigger rolls. Smaller pads. Camouflage colors. Safety messages printed on the surface. Perforations. Dispenser boxes. Mainly 30 years without any real innovation. In the mid-1990s, one product manager complained that his boss called a different color covering on the spill sheet a “new product.” Sheesh.

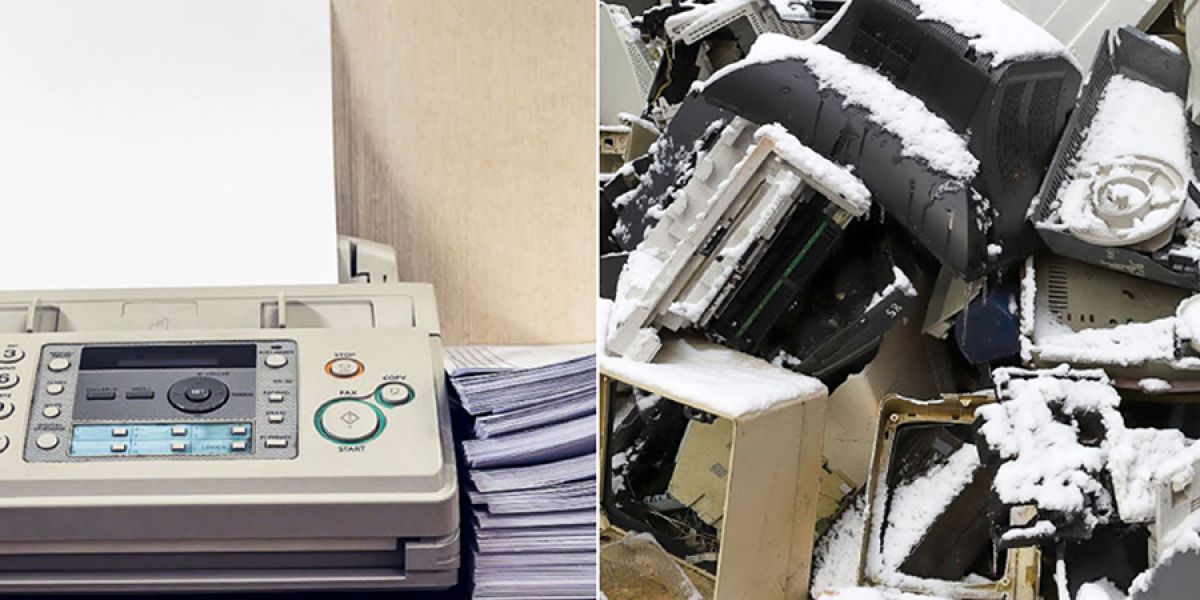

Consider the fact that white oil spill sheets are 15 years older than fax machines and 23 years older than bag phones.

It’s Time for an Upgrade

Maybe it’s time for an upgrade of your old white spill sheets. I’ll bet you are not still using a bag phone. So, why not upgrade your outdated white spill sheets. Now is a perfect time.